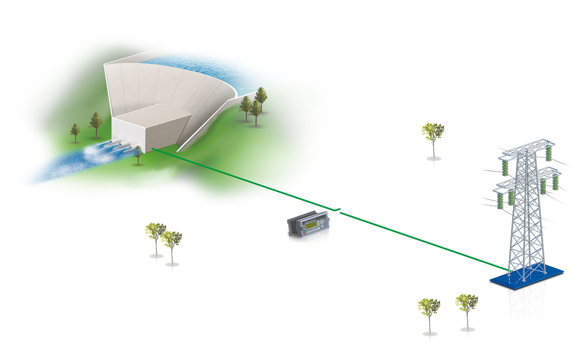

DEIF controllers help tame Washington's Colville River at a remote hydro plant

Hydro Technology Systems uses the DEIF GPC-3 on two Francis horizontal turbines at Meyers Falls Hydro Electric Plant

Nestled deep within the Colville National Forest along the Colville River in Washington State, the Meyers Falls Hydroelectric Plant runs in relative silence, its generators making a constant low humming that gets drowned out by the sounds of constantly pounding water from the nearby towering waterfall. Taming those waters through finite control to generate energy is where DEIF plays a role.

For the past 100 years, Meyers Falls Hydroelectric Plant has withstood the test of time, creating clean, renewable power to homes and businesses in nearby towns like Kettle Falls, Greenwood and Colville, located about two hours north of Spokane. Known as the oldest continuously operating waterpower site west of the Mississippi River, the Meyers Falls Plant now delivers power to more than 1,000 homes and businesses in the region. The output generated by the plant goes directly into the grid.

The plant is owned by Hydro Technology Systems, a family operation that has been a DEIF customer since 2003. That’s when two DEIF GPC-2 controllers were installed to handle the inflows and regulation of power generation from two 180 kW/480V direct-coupled horizontal Francis turbines. Former plant Owner and Director Mike Johnson and current Hydro Technology Systems Owner and President Ben Hendrickson agreed at the time that DEIF’s controllers could provide the right protection and control, relaying, and voltage regulation in one integrated system. They were so impressed with the controllers’ performance that in early 2021 the decision was made to upgrade the GPC-2 controllers with two new GPC-3 models, giving them even more flexibility in managing the operation of the plant.

“DEIF is a great solution for a small hydro operation like us,” Ben says. “All of the features in the new GPC-3 controller make for a great product. From water level to VAR control, to the control of the turbine genset, it has been the right solution for us all these years.”

The variability of the Colville River and its seasonal water levels have always remained a concern for a hydro operation like the one at Meyers Falls. Relying on Mother Nature to deliver a level and consistent flow of water all year round would be futile. Mike Johnson, who bought the plant from a local utility in 1999, was immediately drawn to the DEIF water level control functionality in the GPC controller unit.

“With the water level control built in, DEIF controllers automatically adjust the water flow through the turbine according to the river flow conditions,” Mike explains. “That was a big deal. Some of the other features, like the protection package, give it full protection in terms of frequency, overvoltage, undervoltage, and regulation of current, all necessary for power plants.”

The DEIF GPC-3 controllers moderate the wicket gates of the turbo hydro generators via a PID (proportional, integral and derivative) loop. When more power is required, like in a diesel engine configuration, the GPC-3 commands the opening of the wicket gate (a series of adjustable vanes), sending in more water to the turbine, thus generating more power. This type of command operation is built into the controller, requiring no reprogramming.

One of the major requirements of the DEIF controller that was mandated by Hydro Technology Systems was the protection and control functionality of the unit. This built-in P&C eliminated the need for extra control boxes and software, which is a space and cost savings.

Behind the DEIF display units sits the cabinet housing for the wiring and other electronics. The GPC-3 base boxes are located there and are connected via TCPIP, incorporating the programming and functionality, like external protections, voltage regulators and PID loops for the two controllers.

Ben believes one of the primary benefits of the DEIF GPC controller is the unique all-in-one component-based system design. Without DEIF in the picture, Ben and Mike would have been forced to acquire and integrate programmable logic controllers, a separate generation control package, protection and AVR (automatic voltage regulator) control. “We’d have a cabinet full of equipment and would have likely spent quite a bit more for the PLC package” due to the extreme cost of separate units, Ben explains.

The plant uses DEIF’s utility software v.3 (USW-3), which is a unique tool for end-users and others in order to configure and supervise one or several interconnected genset controllers. On the easy-to-use USW interface, a device overview page allows users to view the AVR and regulator status, monitoring in real time the voltage frequency, breaker status and much more. With a direct connection to the GPC-3 controllers, the USW remains open all the time on a computer station near the controller cabinet, and Ben and Mike can make any changes needed, accessing it locally – or even remotely if needed.

“DEIF has been a great partner for us at Meyers Falls,” Ben says. “The package they provide in the GPC 3 has worked out very well. The features, the protection and control part of it are wonderful, and when you add in the water level control, VAR control, and all the other features, it’s a great product and we’ve been very happy with it.”

Ben sees a bright path ahead for the future hydro in the United States. “It is a great potential in this country,” he says. “Hydro is clean, renewable, old technology, so it’s base load, meaning it runs 24-hours-a-day, seven days a week. It’s a beautiful thing when you can take water through a turbine and cause no environmental impact. It is great technology.”

Read our hybrid power guide

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark