Be independent of PLC vendors with CODESYS

As long as your PLCs work as they should, and your requirements don’t change very much, being tied to one particular PLC hardware vendor is usually not a problem. You know what you’ve got, and what you’ll be getting if you need more. But you may well find yourself in a situation where it would be advantageous to consider switching to another PLC brand:

- You may need PLCs that offer more, or other, features than your current solution.

- Your current PLCs may be outdated so you can no longer get replacement units.

- You may be dissatisfied with your current PLC vendor because of support or pricing issues.

Or you may quite simply be unable to source the PLCs you usually rely on because supply chain issues cause unacceptable delivery delays.

Porting existing logic is a key consideration

In all of these situations, you need to switch PLC brands quickly and with a minimum of disruptions, and this includes finding a way to port existing PLC logic to your new controllers. You don’t want to spend time and money reprogramming everything from scratch, and you certainly don’t want to risk breakdowns! This critical portability issue can be solved by using hardware-independent logic, and that’s exactly what you get with CODESYS.

Your options with CODESYS

CODESYS is an IEC 61131-3 compliant hardware and manufacturer independent development environment that lets you program PLCs in several programming languages. It adapts easily to different system requirements and environments and gives you everything you need in a single user interface. This lets you develop the control and automation solutions you need; for more information on some of the key advantages of programming with CODESYS, see this blog post.

More importantly, you can easily migrate existing PLC logic to new CODESYS-based controllers, even if your logic is based on a different platform. And once you have migrated to CODESYS, choosing and switching controller brands becomes much easier. But how do you do it? Here’s a quick overview of your migration options.

- Need to migrate from another solution?

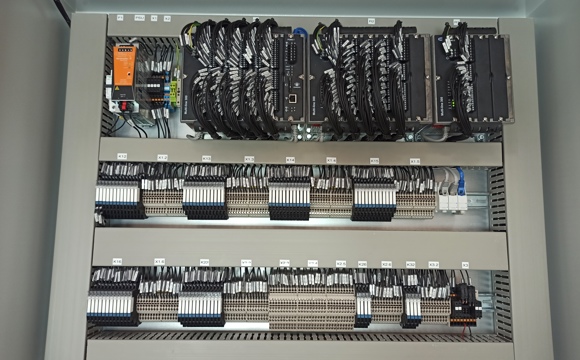

Migrating from other PLCs that do not use CODESYS as runtime requires a little manual work, but it is often easier than you might think. Once you have configured your new I/O in CODESYS, you simply need to port your existing PLC logic step by step.

You can re-draw function block diagrams one to one, and text-based programming languages similar to Structured Text can be transferred POU by POU (programme organisation unit). In practice, the migration involves copying and pasting logic from the IDE (integrated development environment) of your old PLCs to the CODESYS IDE. You can quickly implement syntax changes using search and replace.

While this may sound very time-consuming, a structured approach to the migration, and the user-friendly CODESYS environment, will take you a long way. If you need more information or assistance, let us know. We have frequently guided or assisted customers in becoming hardware independent by converting existing customer projects to CODESYS, ready for implementation or continued development.

- Using an earlier CODESYS version?

If you’re already using CODESYS but would like to upgrade to a newer version, the process is very easy. You can automatically import code from CODESYS V2 projects (.pro files) to CODESYS V3. In fact, CODESYS V3 includes an import tool that guides you through the process.

The only thing you need to be aware of is that the import tool is only available in the 32-bit version of the CODESYS V3 environment. After you have carried out the import using the 32-bit version, you can maintain and develop the project in the 64-bit version of CODESYS V3.

- Already using CODESYS V3?

If you’re already using CODESYS V3 as PLC run-time, congratulations – you are using a platform that lets you easily migrate your logic to other PLC brands as and when needed. You can simply apply another controller as a second source by right-clicking the top device in the CODESYS IDE and updating it to the device description of the new controller. Of course, you may need to adjust to I/O module mappings and take vendor-specific libraries into accoun

A long history with CODESYS

In short, migrating existing logic to CODESYS to achieve independence of PLC hardware vendors is possible and, in most cases, not an obstacle that should keep you from taking full control of your PLC purchasing strategy. At DEIF, we have been advocating independence of hardware and software vendors for years. As part of this approach, we have been using CODESYS V3 since 2010; in fact, we were one of the first companies to apply it, and over the years we have seen it improve and mature.

Take control of your PLC sourcing strategy

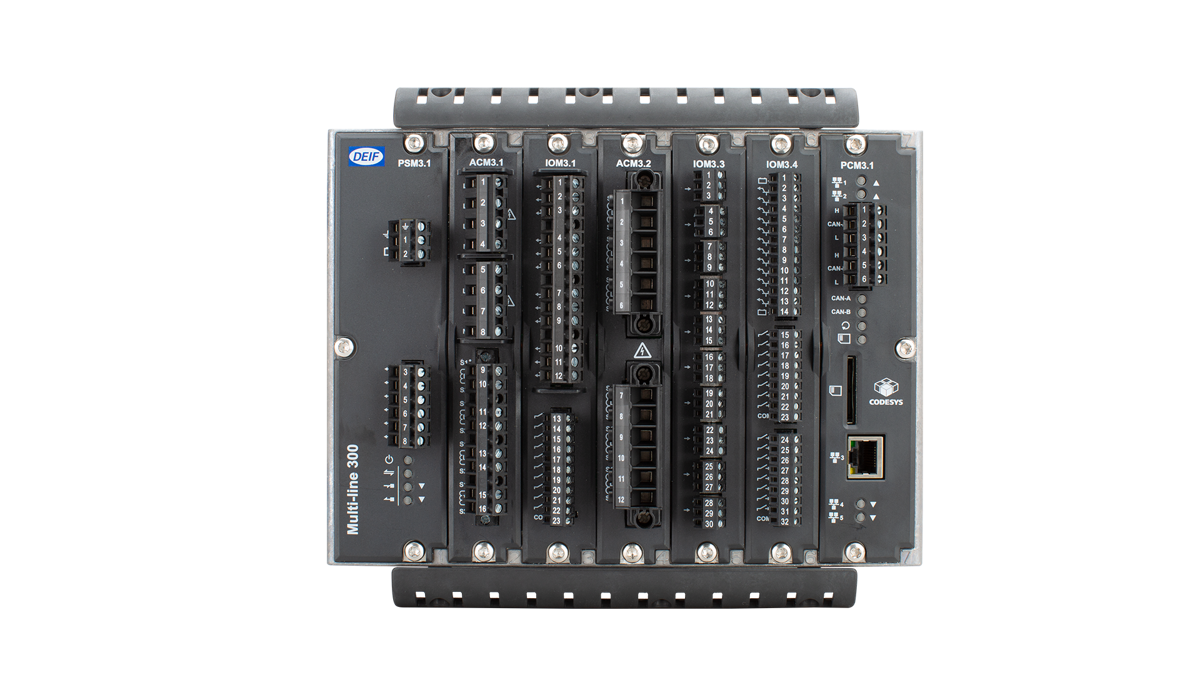

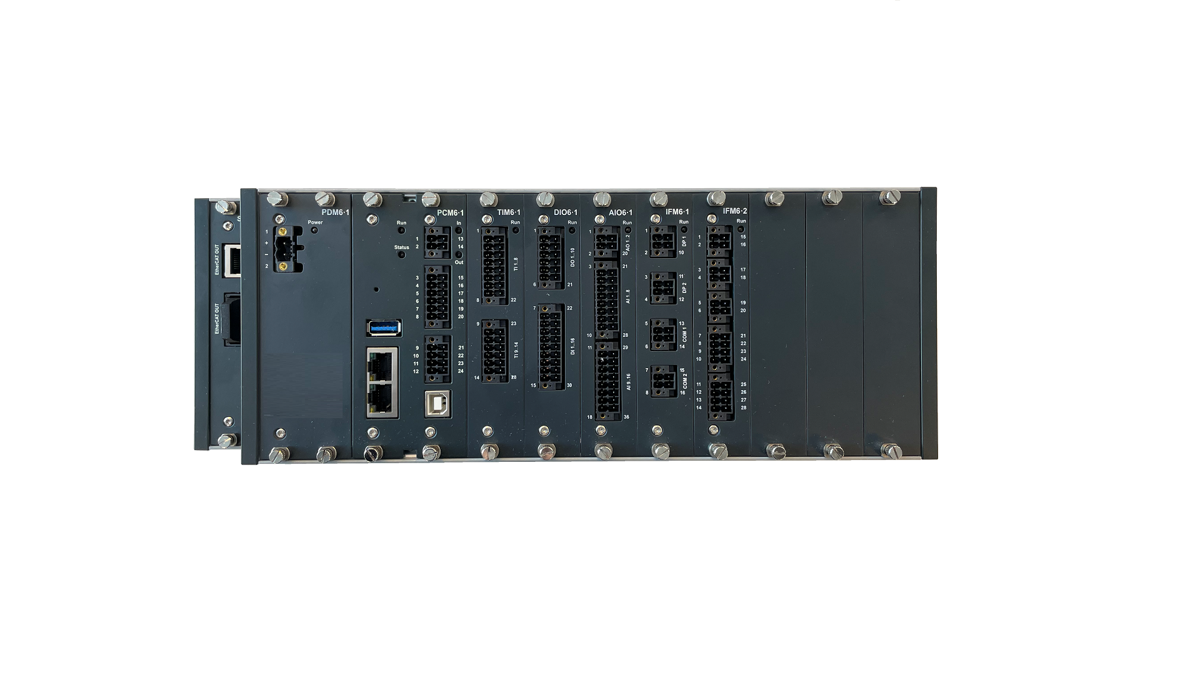

With CODESYS-based PLC logic, you are free to select PLC hardware vendors as you please. DEIF offers solutions such as the AMC 300 and AMC 600 (both of which use CODESYS V3 as PLC runtime and can be configured as needed for almost any control application), but once you have migrated to CODESYS, you can select any compatible PLC brand you like. This gives you the freedom to take control of your PLC sourcing strategy and adapt to requirement changes, outdated hardware, lack of support, or any other external factor that forces you to review or change your assets – now and in future.

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark