There has never been a more profitable time for a turbine controller retrofit

As a wind farm owner and/or operator, you want to run your turbines as efficiently as possible. Very often, however, the OEM (original equipment manufacturer) controllers in your turbines prevent you from taking control of your service and maintenance, tracking performance data, and optimising your turbines – among many other restrictions.

You can easily and successfully solve this by replacing the OEM controller with a new one that gives you full access to control the turbine and lets you boost AEP (annual energy production), reduce OPEX (operating expense), carry out service yourself, extend the lifetime of the turbine, and get full control of your assets. And now really is the time to do it: Energy prices are soaring, giving you more money for every produced megawatt-hour and allowing you to achieve ROI (return on investment) even in a matter of months! A small retrofit investment is always worthwhile for your project, and now that is even more true.

Reversing a downward trend

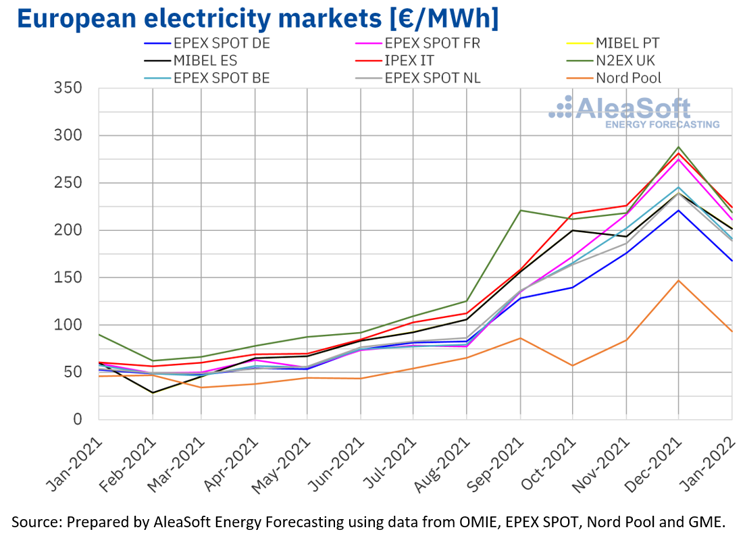

Energy prices have been decreasing steadily for some years, but that trend has now been reversed. At the beginning of the century, feed-in tariffs were near €100 per MWh but dropped slowly every year. By 2019, many wind parks were out of the feed-in tariff system and subject to market prices which dropped steadily until they stabilised around €50 per MWh in the first half of 2021.

At this point, a rapid price increase set in, with N2EX UK prices peaking at just under €300 per MWh in December 2021 – roughly three times as much as the feed-in tariffs at the turn of the century.

In some markets, prices are more than 10 times higher than the average on some days. And even though prices have dropped since December 2021, they are expected to remain high for at least the rest of 2022.

Implications for wind parks

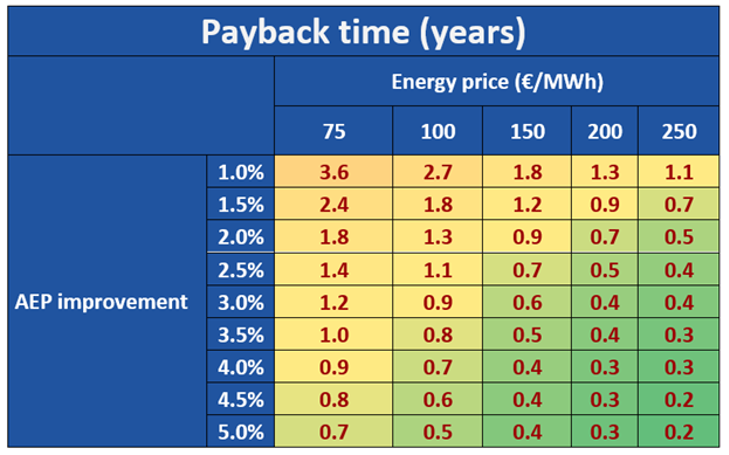

What does this mean for wind park owners and operators? Well, with the forecast price increases in 2022, an AEP improvement of just a couple of percent multiplied by high power prices means that ROI can be achieved in a matter of months as shown in the table below (with calculations showing an average wind park with 2MW turbines).

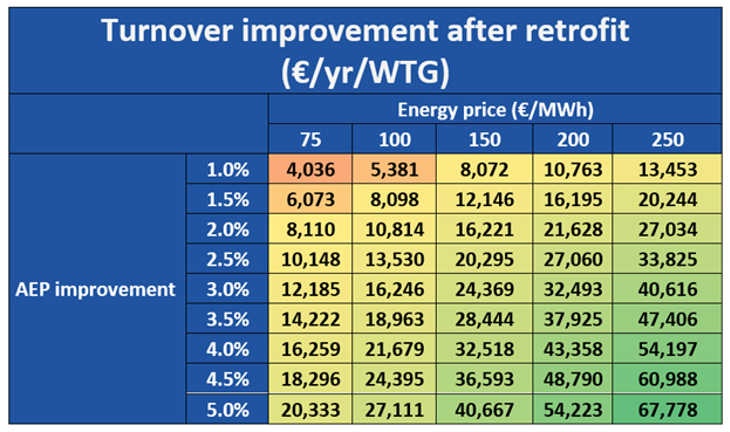

This calculation does not consider the usual financial improvements that retrofitting with an open controller can provide; it only focuses on production improvements after retrofitting. Turnover, too, can improve drastically:

As before, these results are related only to production improvements with open controllers, not taking into account many other improvements from open controller solutions which would make ROIs even lower and turnover higher.

Green and simple improvement

Carrying out a controller retrofit is not only a good way of improving productivity, turnover, and ROI – it is also a very climate-friendly way of improving your wind project. Decommissioning old turbines and erecting new ones is a complex and resource-heavy operation that generates significant amounts of waste and carbon emissions. To make matters worse, the efficiency of the new turbines is seldom high enough to warrant the effort, investment, and waste.

A retrofit project, by contrast, lets you realise efficiency gains in a green manner from existing assets with negligible downtime. It is also a quick and easy way of improving your wind site: While supply chain issues can make it difficult to procure new turbines, purchasing and installing new controllers is a much simpler, faster, and profitable matter.

Contact us for more information

In short, there really are a lot of good reasons why a controller retrofit is a great solution for your wind farm, and the current financial situation makes it an even more attractive option. Contact us if you would like to boost productivity, reduce cost, extend turbine lifetime, and get full control of your assets – and get your money back surprisingly quickly.

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark